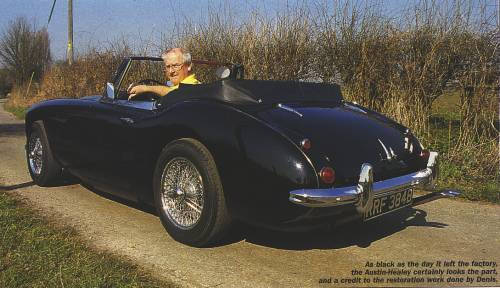

Members Motors. Northern Centre Director, Denis Austin.

Article extracted from Classics magazine.

December 2003 and reproduced here with their kind pemission.

“When

the engine was lifted out the mountings fell off the chassis.”

Denis

Austin went from building model traction engines to restoring an Austin

Healey and found several trials and tribulations along the way, as David

Bowers reports.

.

Denis

Austin was finishing a model traction engine when a friend suggested

restoring a car would make better use of his talents. Denis pictured himself

in an Austin Healey 3000 with the long bonnet stretching out ahead as the

car ate up the cross-country miles.

He

was cautious in choosing a car; “I spent 12 months travelling up and down

the country looking at expensive heaps of junk, trying to convince myself

they were restorable. Then I found this 1964 Mk111 model, re-imported from

the United States.”

A

Heritage certificate confirmed the car’s provenance. When exported to

Wisconsin in 1964, it had been black rather than the bright red it now wore.

It was complete and all the serial numbers matched the documentation,

impressing Denis; “The rear axle was one digit out, presumably due to a

clerical error.”

First

moves at dismantling were tentative, but Denis was soon contemplating a pile

of panels and the enormity of the task ahead. Extensive corrosion was only

part of the story; “I hadn’t realised the car had been hit on the

nearside front and badly damaged. The scuttle support panel was out of shape

and the chassis rails kinked. When the engine was lifted out, the mountings

fell off the chassis rails. Only its own weight held it in place, you could

see where it had been thrown forward bending the cross member. Someone had

put on a new front wing but done little else. Imagine using a car in that

condition.”

The

car was sent away for the chassis to be jigged into shape and on its return

Denis put welding skills learnt at night school to use. To stop the body

from sagging, it was braced with two-inch angle iron supports, transversely

across the cockpit and longitudinally along the door frames, followed by

welding in new sections, a bit at a time, where the chassis had rotted away.

A new nearside scuttle support section replaced the acci dent-damaged

item and the rotted-away bottom half of the pedal boards made way for new

metal. New floor panels and a back seat support panel were welded into

position. Removing the inner and outer sills proved a struggle, but the new

ones easily slipped into place.

dent-damaged

item and the rotted-away bottom half of the pedal boards made way for new

metal. New floor panels and a back seat support panel were welded into

position. Removing the inner and outer sills proved a struggle, but the new

ones easily slipped into place.

Repair

sections were needed along the front chassis rails where the suspension,

steering and engine mountings attached. The new mountings had to be

precisely located so Denis took dimensions from a workshop manual, then

fabricating two jigs to accurately locate the mountings on the chassis

rails.

Other

welding jobs included fitting a new crucifix support structure in front of

the radiator, and a set of door shut panels. “Forget what they say about

Stateside cars not rotting,” said Denis. “This car came from North

Carolina, which is not a dry state. American cars rot from the inside out

due to water getting in, ours rot from underneath because of the salt put on

the roads.”

By

now Denis had decided that the aluminium front and rear shrouds required

specialist panel beating so they were repaired by Northern Healey of

Castleford, Yorkshire.

Completing

this stage of the restoration was a major feat, particularly for Denis who

as a schoolboy had lost his right leg in a road accident. He doesn’t dwell

on the subject, preferring to joke about when a splatter of molten weld set

his trousers and the foam padding of his artificial leg on fire.

In

view of his disability Denis planned a conversion to right-hand drive, hand

controls and power steering. But Denis Welch Motorsport of Burton-on-Trent

advised that power steering would be prohibitively expensive. Before

starting the right hand drive conversion, Denis sat in another Healey, and

discovered it was almost impossible to get his artificial left leg into it,

so the conversion idea was dropped. The hand controls were installed by a

specialist who was similarly disabled.

Denis

started to repair the wings, then changed his mind; “I was becoming a

perfectionist and they were not up to standard.” AH Spares supplied new

front and rear wings which with the other panels were individually resprayed

before being refitted to the repainted shell. Finding a firm to do the

respray wasn’t easy, due to the difficulty of getting a perfect black

finish. WG Bodies of Stoke-on-Trent achieved a fine result in two-pack, far

cheaper than the £3,500 quoted by one firm.

Fitting

the trim piping that sits between the steel wings and the aluminium shrouds

to prevent corrosion and absorb vibration, provides on of the worst

memories. “The piping came with a roll of sticky material to secure it in

place. But it adheres instantly, so it’s very difficult to make final

adjustments between the piping, the wing and the shroud. One area I’m not

satisfied with, but no-one else notices.”

Suspension

work proved refreshingly straightforward. The parts were stripped down an

rebuilt with new bushes, the only new items needed a set of rear springs.

After

replacing the steering arms, the brakes were overhauled with new front discs

and slave and master cylinders rebuilt with new seals, all supplied by AH

Spares. Denis replaced the brake lines, fuel pipe and also the tank after a

hole was found.

Denis

was initially confident that the engine needed little work; “The money had

started to run out, so after checking the compression, the bearings, oil

pump and other components, I fitted new valves and a clutch, as I couldn’t

see anything else wrong.” But some time later the engine started laying a

smoke screen due to piston ring wear. So Northern Healey rebored the block,

adding a new crankshaft and oversized pistons, a Kent fast road camshaft and

lightened flywheel, and raising the compression by skimming the cylinder

head, all resulting in performance much improved over a standard car. The

gearbox and overdrive unit needed no work but new universal joints were

added to the propshaft.

Denis

replaced the wiring loom after removing the dashboard. This was re-veneered

by an ex Rolls-Royce employee and the instruments sent to be reconditioned

and recalibrated. Willtrim of Castleford did the upholstery; “They made a

beautiful job of re-trimming the seats, door cards and dash centre panel in

Ambla fabric, as originally fitted. I had thought of going for leather, but

they advised not to, as raindrops cause stains.”

The

final jobs before the MOT included fitting new headlights, fog lights,

indicator units, front and rear bumpers and the rechromed badges and trim

items.

Shortly

after the car returned to the road, disaster was narrowly averted when a

stub axle worked loose. “The steering wheel started shaking. I couldn’t

find anything wrong with the steering or front suspension, but I then

discovered a rear stub axle was

held on by a single nut. A few hundred yards more and it would have spun

off. Both stub axles were re-secured with special nuts and Loctite glue.

When I told other owners they said, ‘That happened to us, didn’t you

check them?’ Everyone seemed to know about this but me.”

After

finishing the five-year project, Denis got involved with the Austin Heale y

Club events and a highlight was when the car took first prize in the

club’s national concours at Tatton Park in 1999. He was also at 50th

anniversary celebrations at Wokefield Park, Reading last year, featuring

more than 700 Healeys. The memorable event included taking the cars round

the nearby Thruxton race track.

y

Club events and a highlight was when the car took first prize in the

club’s national concours at Tatton Park in 1999. He was also at 50th

anniversary celebrations at Wokefield Park, Reading last year, featuring

more than 700 Healeys. The memorable event included taking the cars round

the nearby Thruxton race track.

Denis

is Northern Area Director of the Austin Healey Club and with the club has

taken the car on tour of Europe including runs on the Spa circuit in Belgium

and the Nurburgring in Germany. He rallies the Healey and Avon ZZ tyres were

fitted to the replacement wire wheels. They were expensive but provide

excellent grip.

Asked

whether it was all worth it, Denis has no reservations; “It’s a lovely

car to drive and has provided lots of pleasure at club events or driving in

the Peak District. Performance is excellent and although fuel consumption is

only 19 mpg, you have to remember that the engine is a 3-litre. The car has

never missed a beat, the shape is in the classic Healey mould - the car

I’d always promised myself.”